Every modern facility — whether a mall, university, manufacturing plant, or hospital — depends on reliable electrical power to function. Yet reliability is not only about supply availability; it is also about the quality of that supply. Poor power quality can silently erode equipment life, inflate energy bills, and cause production losses.

At Jumba Engineering Services Ltd., we have seen too many projects in Kenya where power quality analysis was ignored at the design stage, leading to costly retrofits and operational inefficiencies later. As a firm with over 40 years of electrical contracting and consulting experience, we firmly believe that power quality audits should be integrated into every project design.

What is Power Quality?

Power quality refers to the stability and cleanliness of the electrical waveform supplied to your facility. A “clean” sine wave at the right voltage and frequency is what equipment is designed for. Any deviation introduces risks.

Key power quality issues include:

Harmonics: Non-linear loads (like VFDs, UPSs, LED drivers) distort waveforms.

Voltage sags & swells: Caused by grid instability or heavy load switching.

Transients: Sudden spikes due to lightning or switching.

Flicker: Rapid voltage changes affecting sensitive loads.

Poor power factor: Excessive reactive power leads to higher utility bills.

Why It Matters

Ignoring power quality has both technical and financial consequences:

Reduced lifespan of motors, transformers, and electronics.

Nuisance tripping of protective devices.

Downtime and production loss in factories.

Higher operational costs due to penalties (power factor <0.9 in Kenya leads to surcharges).

Safety risks from overheating cables and equipment.

In critical facilities like hospitals or data centers, poor power quality can literally mean life or death.

Standards and References

Jumba Engineering follows internationally recognized standards in power quality design and analysis:

IEEE 519: Recommended Practices for Harmonic Control.

IEC 61000 series: Electromagnetic compatibility standards.

IEEE 1159: Power Quality Monitoring Guidelines.

EPRA Regulations (Kenya): Requirements for utility compliance and penalties for poor power factor.

Jumba Engineering’s Design Philosophy

When JES Ltd. undertakes design and consultation, power quality analysis is embedded from day one. Our approach includes:

Load Profiling – identifying types of loads (linear, non-linear, inductive, capacitive).

Harmonic Simulations – using software tools to predict harmonic levels under various operating scenarios.

Power Factor Correction – capacitor banks, active filters, and demand-side optimization.

Relay Coordination Studies – ensuring protective devices trip selectively and reliably.

Surge & Transient Protection – integrating surge protective devices (SPDs) per IEC 62305.

Testing & Commissioning – post-installation power quality audits to validate design assumptions.

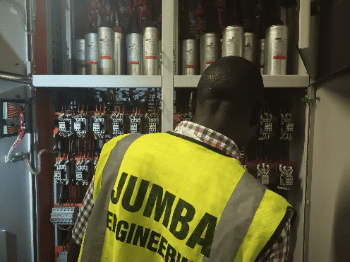

Case Study: Garden City Mall LV Board Testing

In 2023, Jumba Engineering was contracted to perform testing and inspection at Garden City Mall. The facility had been experiencing nuisance tripping and excessive transformer heating.

Findings:

Harmonic distortion exceeded IEEE 519 limits (THD > 8%).

Power factor was averaging 0.82, leading to significant utility penalties.

Solution by Jumba Engineering Ltd.:

Installed active harmonic filters.

Upgraded capacitor banks for automated power factor correction.

Calibrated protective relays for better selectivity.

Results:

Reduced THD to <4%, well within IEEE standards.

Improved power factor to 0.96, saving the client over KES 500,000 annually in penalty charges.

Increased system reliability, reducing downtime by 70%.

Benefits to Clients

By integrating power quality analysis into design, Jumba Engineering ensures:

Lower operating costs through efficient power usage.

Extended equipment life, reducing replacement costs.

Improved reliability, avoiding costly downtime.

Regulatory compliance with EPRA and international codes.

Peace of mind knowing your system is resilient to disturbances.

Best Practices for Facility Owners

Always request a power quality audit before commissioning major projects.

Invest in monitoring equipment to track harmonics and power factor.

Schedule annual inspections of capacitor banks and filters.

Train your facility managers on recognizing PQ issues (e.g., lights flickering, overheating panels).

Partner with EPRA A1 licensed contractors like Jumba Engineering for design and corrective actions.

Why Jumba Engineering is the Partner of Choice

As Kenya’s leading electrical design and consultation firm, Jumba Engineering brings:

A team of EBK-registered engineers with decades of experience.

Cutting-edge tools for harmonic simulations and relay coordination.

Proven track record in malls, universities, solar plants, and government institutions.

A culture of safety, precision, and client-centered design.

Conclusion

Power quality is not an afterthought — it is a design cornerstone. By addressing it upfront, Jumba Engineering saves clients money, protects investments, and ensures compliance.

📧 Ready to safeguard your project from hidden electrical risks? Contact us today at jes@jesltd.co.ke or request a consultation via our Request a Quote page.